|

Initial

research

As a PhD student at the University of Sydney in 1967

Graeme Clark began to review the available research

to "investigate whether a single or multiple-channel

(electrode) cochlear implant would be possible for the

management of a profound hearing loss." (Clark,

1969: 1)

Since

1970 he has led the research in the Department of Otolaryngology

at the University of Melbourne that has resulted in

a multiple-channel cochlear implant that can provide

significant understanding of speech for severely and

profoundly deaf children and adults.

Inspiration

When Australian otolaryngologist Graeme Clark began

developing the cochlear implant or as it was more commonly

known — the bionic ear — overseas researchers

used an implanted device that had wires leading from

the inside to the outside of the head. According to

Clark this presented too many opportunities for infection.

He believed that the implant should be totally imbedded

and receive information via radio signals rather than

linked to an external source. Other researchers also

had different ideas about where the electrode should

be placed. Some placed it outside the cochlea, others

directly onto the auditory nerve.

| Clark

believed that the electrode should be placed into

the cochlea but could not work out how to get the

electrode inside the tiny spiral without opening

it up. He was inspired by nature to find the solution.

When at the beach he picked up a seashell that resembled

the shape of the cochlea. Nearby was a clump of

wild grass that he pulled a few blades from. As

he twined the blades through his fingers he noticed

that they changed stiffness along their length and

were tapered at the top. Looking at these things

he had the idea of carefully inserting the blade

of grass into the shell until it went almost completely

into the spiral. After this he imagined a bundle

of electrodes of fine, strong and flexible wire

that could be inserted into the human cochlea by

easing around the corners and positioned to correctly

stimulate nerve endings. |

|

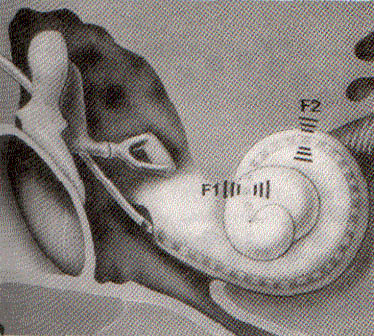

Electrode stimulation pattern resulting

from sound 'ah' (Cochlear Pty Ltd)

|

Resolving

problems

Ethics

Based on the research he had conducted for his PhD,

Graeme Clark and his research team at the University

of Melbourne began fine tuning the design of the implant.

Using Clark's inspiration of the shell and blade of

grass they began to explore the notion of an electrode

array.

As

the

…whole project was still in the research stage,

the Australian team determined to follow the ethical

recommendations made at the Declaration of Helsinki

in 1964 for guiding doctors in clinical research,

as well as the recommendations in the Statement

of Human Experimentation published by the National

Health and Medical Research Council of Australia in

1976. (Epstein, 1989: 44)

As

animal experimentation was needed before the implants

could be used on humans there were also animal ethics

to consider.

For

more information on animal ethics:

Animal

Ethics Committees Manual of Policy and Procedures, The

University of Melbourne, March 1996

Technical

considerations

Some of the problems the research team had to overcome

included:

- the

electrode bundle had to be precisely manufactured

- the

materials needed to be resistant to body fluids and

harmless to the recipient. Clark and his team used

Teflon® coated platinum wires as electrodes to

fit in the cochlea. The multi-electrode array successfully

passed into the cochlea. To resolve the problem of

finding materials resistant to body fluids the designers

looked to work being done on the pacemaker implant.

It was originally cast in epoxy resin, however the

cochlear implant researchers believed a metal may

offer lightness and body fluid resistance. Pure titanium

was trialled for the casing by G. A. and L. Harrington.

G.

A. and L. Harrington was the first company to "deep

draw titanium in Australia. In this process which

requires special expertise, sheet metal is turned

into the required shape with a high depth to width

ratio." (Epstein, 1989: 48)

- the

feedthrough wires had to be insulated - high alumina

ceramic was selected. The Ceramic Corporation Pty

Ltd, specialists in precision industrial ceramics

were approached. The owner, Miroslav (Mirek) Kratochvil

emigrated to Australia as a political refugee from

Czechoslovakia, developed a new ceramic which was

fired at a much higher temperature than normal to

give the properties needed.

- welding

the parts together. A new alloy was developed and

trialed. These three components ensured

…a hermetically sealed implant, completely resistant

to body fluids. …These discoveries were to have

an enormous influence on the development of the Australian

bionic ear, for the electronics to be used in the

implant would also need the protection which only

the hermetic seal devised for the pacemaker could

give. (Epstein, 1989: 49)

- tests

had to be done to determine how to best reach the

cochlea in surgery.

- clinical

trials and selection of suitable recipients had to

be carried out. These trials have influenced current

procedures as well. An effective service network was

an essential ingredient to ensure that the innovation

would fulfil a user's needs.

- the

implant would need to last a long time — a design

life of 70 years.

Funding

the research

Funds were needed to continue the project. Funding was

donated by Melbourne Apex Club, a telethon organised

by Sir Reginald Ansett and Channel 0, The National Health

and Medical Research Council and Lions Clubs International

and at a later stage the Deafness Foundation of Victoria.

Distribution

clinics, an innovation too

The success of the Cochlear implant is founded on a

world wide network of dedicated clinics. At these clinics,

the Cochlear implant is implanted by a surgeon. More

importantly, each recipient is trained by an audiologist

to recognise speech using the system. Training is needed

to recognise the unfamiliar sounds generated by the

speech processor. Try to recognise the nursery rhyme

in this simulation of processed speech.

|

Each

system is customised to suit the individual and

fine-tuned to convey the maximum amount of speech

information. Regular repeat visits ensure that

the system is operating at its peak.

The

success of the Cochlear implant system rests on

careful selection of appropriate patients, reliable

technology, and a network of clinics staffed by

highly skilled surgeons and audiologists.

|

(Cochlear

Pty Ltd)

(Cochlear

Pty Ltd) |

Developing

a prototype of the cochlear implant

The receiver-stimulator in the prototype device needed

…the

equivalent of 6000 radio valves to make it work, a

sheer impossibility until the development of integrated

circuit technology when that same amount of electronic

circuitry could be condensed into a tiny microchip.

(Epstein, 1989: 43)

The

receiver-stimulator was designed and manufactured by

Melbourne University's Department of Electrical Engineering

and Department of Otolaryngology.

A

prototype receiver-stimulator with a connector for

10 channel electrodes, all to be implanted, and the

University of Melbourne was able to lodge an application

for patent rights. The device was called Umdolee (University

of Melbourne Departments of Otolaryngology and Electrical

Engineering).

The

gold box multiple electrode device measured 4.2 x

3.2 x 0.85 to 1.3cm. It included a sandwich of three

razor-thin substrata and the thousands of transistors.

The electrodes themselves consisted of a bundle of

twenty fine wires, each insulated and fine as a human

hair, the diameter of the whole bundle being about

0.5 mm. This bundle had to replace the work of some

20 000 to 30 000 nerve fibres in the normal ear and

transmit sound impulses to the brain. …each pair

of electrodes controlling a sound of a different pitch.

(Epstein, 1989: 43)

The

speech processor, however, had not been developed. This

was the device to break speech into meaningful signals

that the brain could recognise. The strategies to teach

someone how to recognise speech could only be developed

when a person who had received an implant worked with

engineers and audiologists.

Finding

the first patients

To ensure testing was rigorous and accountable, assessments

for selection of patients and monitoring implantees

was carried out in a multidisciplinary centre featuring

specialists in:

- phonetics:

the study of speech sounds and their production

- audiology:

the diagnosis and rehabilitation of hearing loss

- auditory

physiology: the physiology underlying normal and impaired

hearing, speech and language in humans. Physiological

measurement techniques are used to identify and assess

hearing impairment.

- information

science: the collection, organisation and analysis

of data.

- otology:

the diagnosis and treatment of disorders of the ear.

- psychophysics:

how electrical stimulation by the cochlear implant

is received by the user and how best to present speech

information to them.

- psychology:

patient support and family counselling.

- psychoacoustics:

conducts basic and applied hearing research specifically

aimed at understanding and correcting impaired hearing.

- speech

rehabilitation: re-establish speech patterns.

- electrical

engineering support: identify and modify hardware

and software problems.

Once

the prototype was developed and extensive animal testing

proved satisfactory the device was ready for implanting

in a human. Rod Saunders received a ten channel implantable

device in 1978. The surgery was a success and Rod heard

his wife speaking to him after the device was turned

on.

For

a more detailed history of the cochlear implant:

http://www.medoto.unimelb.edu.au/info/history2.htm

and for a History of the University of Melbourne/Cochlear

Limited Cochlear Implant

http://www.medoto.unimelb.edu.au/info/history3.htm

|