To

allow the implant to be improved and made accessible

to more people it was necessary for it to become a commercial

enterprise. Commercialisation of the cochlear implant

was essential if it was to be an economically viable

project. However the Australian market was too small.

Nucleus

Ltd

Nucleus Ltd, a group of companies that manufactured

highly developed medical equipment, won a tender to

"carry out a market survey and cost development

plan for the cochlear implant". (Epstein, 1989:

51)

The

four member team responsible for the plan worked on

two tasks:

- research

overseas to study market potential

- a

review of the cochlear implant system design —

resulting in a simplified version featuring a single

integrated circuit.

In

1981, with the University of Melbourne and the Australian

government, Nucleus set out to develop a commercially

viable cochlear implant and to carry out a worldwide

clinical trial.

Reports

were written for both tasks and presented to the Australian

government. Nucleus Ltd was awarded the contract to

develop the cochlear implant.

Cochlear

division of Nucleus

Paul Trainor, Chief Executive Officer, Nucleus Ltd,

formed the Cochlear Division of Nucleus he then

selected a three member Tiger Team.

A Tiger Team, according to Trainor's philosophy, was

a small single-minded group moving forward very quickly

on a specific project and as far as possible not distracted

by the usual day-to-day commitments of a job. They

were relieved of much of the bureaucracy and administration

so that they could concentrate on the main task, and

they were given fully equal or rotating responsibility

for accelerating the work. Naturally, as the project

matured so did the necessity for red tape and administrative

practice, but at the beginning freedom for the job

itself was all important. So the small team began

and at first constructed the device by hand, acting

as designers and manufacturers and checking each other's

work for quality control. (Epstein, 1989: 53)

The

team increased in size and each member was responsible

for a component. The implant was broken down into:

- implant

system design

- integrated

circuit design

- promontory

simulator: a test which demonstrated whether the nerves

of the inner ear were working properly.

- speech

processor: received, processed and stored information

in a way appropriate to each individual implantee.

- external

electric components

- automatic

gain control device: necessary to expand or compress

incoming sounds to an acceptable level.

- electrode

array

- implantable

stimulator. (adapted from Epstein, 1989: 53)

Refining

the mechanics of the implant

A newly emigrated Polish mechanical engineer, Janusz

Kuzma, was responsible for the mechanical aspects of

the implant. He

…had

to devise a way of sealing (the implant) hermetically

with biocompatible material as well as incorporating

a mini antenna coil to pick up the signals. He solved

the latter problem by looping the coil outside the

small round device and enclosing the whole in soft

silastic. A new electrode system with 22 electrodes

had to be accommodated, and he was also responsible

for the design of the external headset. He knew the

electronic parts would not function correctly unless

the mechanical parts were perfect. He knew the team

was dependent on and accountable to public funds.

He knew there was a time limit and time was running

out. He had many sleepless nights. … (Epstein,

1989: 54)

Building

on the University of Melbourne research, Cochlear developed

the more advanced 22 channel implant and the wearable

speech processor (WSP). The design philosophy was to

make a flexible cochlear implant with sophisticated

sound processing in the externally worn speech processor.

This allowed the recipient to take advantage of improvements

in technology without surgically replacing their implanted

device.

Twelve

months after the team began it had managed to completely

redesign the whole cochlear implant system and develop

an implantable device. The system was ready for clinical

trials.

Clinical

trials overseas

Clinical trials of the Australian cochlear implant were

set up in Australia and overseas. Competition in electronic

engineering and microchip technology in medical devices

was world wide and the Australian government wanted

to capture some of the overseas market.

For

the Cochlear implant to be available to the American

market, and indeed world wide the US Food and Drug Administration

had to give its official approval. This was achieved

in 1985.

Cochlear

Ltd today

Since 1988, Nucleus, including Cochlear, had been a

wholly owned subsidiary of Pacific Dunlop. In 1995,

Cochlear was sold by Pacific Dunlop and floated on the

Australian Stock Exchange, as a publicly listed company.

The

Nucleus® 24 Contour implant won the Australian

Design Award™ of the Year in March 2000. It

has some important features:

- an

electrode that is curved before insertion into the

cochlea

- it

places the electrodes closer to the important parts

of the cochlea

- does

not exert any force on the bone or tissue after it

is inserted.

Engineering considerations

Some significant engineering considerations were addressed

in the development of the Nucleus® 24:

| 1. |

Easy

insertion

Ability to insert a pre-curved electrode array

that is designed to fit inside the inner wall

of the human cochlea and has a coating which is

moulded from silicone into the correct shape.

To insert the electrode into the cochlea it is

temporarily held straight using a fine wire stylet.

Once inserted, the stylet is removed. The electrode

must be flexible enough to move around the cochlea

without causing trauma and have sufficient memory

to return to its original curved shape. The stylet

also must be easily removable and all components

must be easily manufactured.

|

Simulation

of contour insertion (New York University)

|

|

| 2. |

Biocompatibility

The implant is made from titanium, silicone rubber

and platinum. The sophisticated electronic sub-assembly

is encapsulated by the titanium shell. The electronic

package is connected to the electrodes by insulated

platinum wires about 25 microns in diameter. The

electronic package is implanted into the mastoid

bone in the skull. The titanium shell must prevent

bodily fluids from entering the package, but also

have a connection to the 22 electrode array and

the radio frequency antenna outside the package.

The device also needs to be strong enough to withstand

surgery and implantation and subsequent flexing

for its design life of 70 years.

|

| 3. |

Long

term reliability

The implant is guaranteed for ten years but designed

for a life of 70 years. |

| 4. |

Safety

during insertion and after receiving the implant

After implantation the processor and system must

be customised for each individual. During programming

of the device it is important that the recipient

is not exposed to excessive stimulation which could

be painful. |

| 5. |

Ease

of manufacture

The implant is handmade under a microscope. |

|

Manufacture

of the cochlear implant

Production

of the speech processor

The behind-the-ear (BTE) speech processor differs

from a conventional body-worn speech processor,

as it contains a directional microphone, contained

within the same case as the speech processor unit.

The production processes for each processor are

very similar.

|

|

|

Precision assembly of the

cochlear implant (Cochlear Pty Ltd) |

|

| 1. |

The

ten-layer, double-sided circuit board, which is

the heart of the body-worn processor, is mounted

with six integrated circuit components as well as

capacitors, transformers, resistors and other components.

|

| 2. |

A

pick and place machine is employed to automatically

place and solder components to the gold pads on

the board, according to a program that is loaded

for each different circuit board configuration.

The push button switches, which are eventually operated

by the external buttons, are manually soldered to

the board, as are connectors (which are used to

connect cables to the test system during testing),

a lithium battery and a power transformer. |

| 3. |

The

circuit board, which is made up of flexible and

rigid parts, is tested and then fixed to the plastic

casing. |

| 4. |

The

control panel, with buttons and LCD window is assembled

onto the moulded plastic case. |

| 5. |

The

closed processor is tested to ensure that the circuit

is functioning correctly, before it is baked overnight,

and then re-tested. |

| 6. |

The

small double-sided circuit board of the BTE processor

contains a custom integrated circuit, which is protected

by a blob of semiconductor coating, and other components.

The microphone, potentiometer (an adjustable resistor

which is seen as the dial from the outside), and

switch, are soldered to the populated board and

everything is placed into the case. |

| 7. |

The

RF socket and the battery terminals are connected

to the circuit, before the board is coated. |

| 8. |

The

closed processor is tested, before the cover and

the ear hook are attached. |

Production

of the cochlear implant

The Cochlear implant itself is made up of three

main functional components:

1. the stimulator

2. the antenna coil and

3. the electrode unit.

The

heart of the stimulator is the Cochlear implant

chip, an integrated circuit. The stimulator also

contains a ceramic disk, or feedthrough, with

twenty-four platinum pins to which each of the

twenty-two electrode wires, and two coil wires,

are attached in the final assembly. The stimulator

is responsible for picking up the signals from

the antenna, and sending out the appropriate electrical

energy to the electrodes. The stimulator is encased

in titanium shells, which are laser welded together.

The

antenna coil, which forms the loop of the implant,

is welded to the stimulator, to form a functional

antenna. It is then wound into the shape that

you see in the final implant. An extracochlear

electrode is assembled, using fine platinum wire,

and is also attached to the stimulator. Stimulator

components are prepared and cleaned prior to entering

the clean room. All antenna coil assembly is conducted

in the cleanroom.

|

|

Most

of the assembly operations for the behind-the-ear

speech processor and the stimulator assembly

are done under a microscope. In the stimulator

production and external production areas,

controls are in place to protect the statically

sensitive devices being handled, therefore

operators wear special lab coats, wrist and

heel straps for grounding, and gloves.

(Cochlear Pty Ltd)

|

|

The

cleanroom is a totally controlled environment

with set temperature and humidity levels, where electrode

assembly and final implant assembly takes place. Strict

controls are required during the final assembly of implants

to ensure that the final product is clean, and after

sterilisation, ready for implantation. Full body garments

are worn in the cleanroom, from boots, overalls, hood,

mask and gloves.

The

electrode unit can either be made up of a straight electrode

array or a contoured array.

| 1.

|

Each

platinum electrode wire is welded to a platinum

ring. The wires are fed through the rings, and one

at a time, each wire is attached to one ring. A

lead wire is attached and the whole thing is encased

in silicone. |

| 2. |

This

electrode unit is attached to the stimulator, and

the individual wires are attached to the corresponding

pins on the stimulator. |

| 3. |

The

assembly is electrically tested and then silicone

is injected to insulate the stimulator. |

| 4. |

The

outside titanium shell is laser welded to the stimulator,

and the unit is tested again. |

| 5. |

The

implant assembly is baked overnight in a vacuum

oven, and then undergoes final hermetisation, which

means that the small hole in the stimulator shell

is fused resulting in a gas-tight seal around the

stimulator. |

| 6. |

A

small magnet is then inserted in the outer moulding

and the entire implant assembly is placed in a moulding

die into which silicone is injected, to completely

encase the implant. |

| 7. |

The

implant is bent so that the coil is at an angle

to the stimulator and the magnet is removed. |

| 8. |

The

implant is washed, the magnet reinserted, and the

assembly is electrically tested. |

| 9. |

Finally

the product is packed in a sterile pouch, this complete

assembly is sterilised, and the implant is packed. |

This

is a basic overview of the manufacturing processes involved

in producing the components necessary for a functional

Cochlear implant system, which transmits signals from

outside the body, to the electrode inside the cochlea,

allowing the recipient of the implant to hear. Text

provided by Cochlear

Pty Ltd.

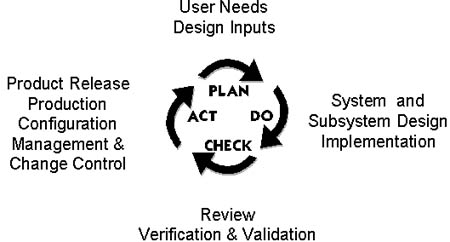

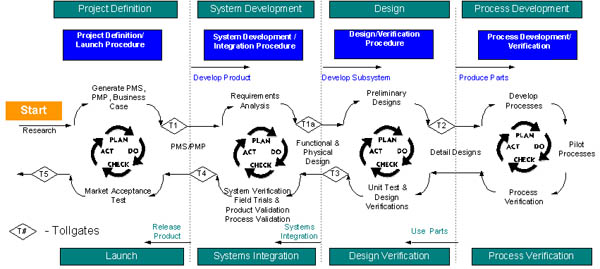

Design process

The following two diagrams illustrate the design process

flow. They incorporate the philosophy of plan, do, check,

act used by Cochlear Pty Ltd.

Process

flow (Cochlear Pty Ltd)

Design process flowchart indicating the stages involved

in developing a product. Note the tollgates or check

points throughout the process. (Cochlear Pty Ltd) Click

image to view enlarged version.

Design process flowchart indicating the stages involved

in developing a product. Note the tollgates or check

points throughout the process. (Cochlear Pty Ltd) Click

image to view enlarged version.

Tollgates

At significant points in the design process Cochlear

has set up tollgates or check points where approval

from a management team is required before the process

can continue. Refer to the design process flowchart

when considering the information in the table.

|

Tollgate

|

When it occurs

|

Approval to proceed to:

|

|

1 |

Project

start |

System

development |

|

1A |

Completion

of system design |

Design |

|

2 |

Completion

of detailed design |

Process

development |

|

3 |

Completion

of implementation |

Pilot

production |

| 4 |

Completion

of pilot production, Clinical trials |

Production |

|

5 |

Completion

of market stability assessment |

Sustaining

engineering |

|