|

Purpose of the Scheme

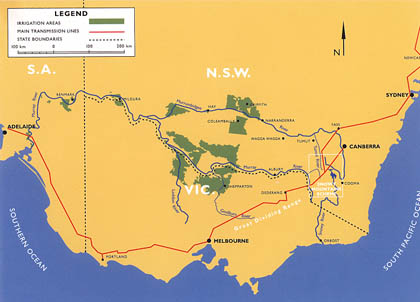

The Snowy Mountains Hydro-electric Scheme (SMHES) is

very large, covering 7 780 square kilometres. The original

purpose of the SMHES was to:

- collect,

regulate, and use the waters of the southward flowing

Snowy River and other streams in the Snowy Mountains

for generating large quantities of peak load electricity

for New South Wales, Victoria and the Australian Capital

Territory

- supplement

the westward flowing Murray and Murrumbidgee Rivers

to enable expansion by irrigation of primary production

on the dry but fertile plains of the Murray and Murrumbidgee

region.

The

Scheme operates entirely within the parameters of its

enabling legislation, the Snowy Mountains Hydro-electric

Power Act 1949 and the Schedule added in 1957.

(SMA, 1993: 8)

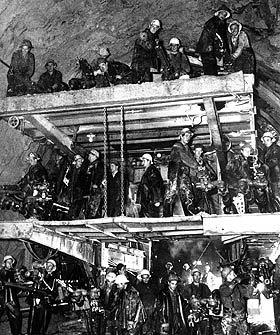

Building

the Scheme

A massive construction program, above and below the

ground, occupied workers for 25 years.

Australian

and overseas contractors built:

- 16

dams

- 7

power stations

- 145

kilometres of tunnels

- 80

kilometres of aqueducts

and

access roads were cut through the mountainous country.

There were many construction records set and broken

on the Scheme.

|

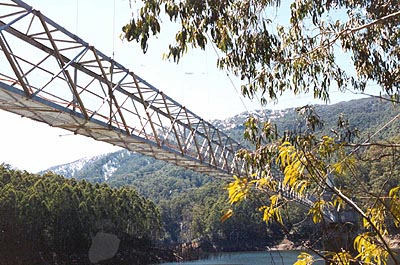

Bridges

Three types of bridge were built by the Snowy

Mountains Hydro-electric Authority (SMA):

- reinforced

concrete or steel girder

- Bailey,

timber or composite

- timber

span or suspension.

Most

bridges in use are concrete or steel girder. Bailey

bridges were originally designed as portable and

usually temporary bridges. One suspension footbridge

has been retained at Geehi Outlet.

|

Suspension bridge (SMA,

1992) |

|

Suspension bridge (SMA, 1992)

|

Dams

Dams are perhaps the most prominent above ground civil

structures on the Scheme. There are sixteen dams spread

over the Scheme with a total storage capacity estimated

to be about thirteen times the volume of Sydney Harbour.

Satellite image of location of dams

(SMA, 1993: 9) |

Types

of dams

There are five principal types of dam, these terms refer

to the chief materials used in the construction of the

dam wall:

Dams on the Scheme

The most common type of dam on the Scheme is the concrete

gravity. Six dams are constructed in this way.

The

highest dam on the Scheme is Talbingo, a rockfill dam,

at 161 metres. The lowest is Khancoban, an earth- fill

dam, at 18 metres. Eucumbene Dam has the largest reservoir

capacity and Deep Creek the smallest.

Activity

Make labelled freehand sketches to explain the difference

between the types of dam.

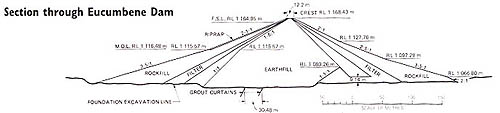

Eucumbene Dam

Lake Eucumbene is the largest reservoir in the Snowy

Mountains Scheme. It holds approximately nine times

the amount of water contained in Sydney Harbour and

covers more than 14 500 hectares. Lake Eucumbene collects

water from the Eucumbene, Upper Murrumbidgee and Snowy

Rivers and its enormous capacity is central to the flexibility

of the Scheme to generate electricity and provide irrigation

waters.

An

earthfill dam

Eucumbene Dam, one of only three earthfill dams on the

Scheme, holds the water of Lake Eucumbene. The other

earthfill dams are at Khancoban and Tooma. Eucumbene

Dam stands 116 metres high and is 686 metres thick at

its base. The outer walls of the dam are built of rock

while the inner core is compacted, impervious clay.

Eucumbene

Dam specifications

Type

Height

Crest length

Base width

Crest level |

Earthfill

116.1m

579.1m

686 m

RL 1 1683.43m |

Spillway

Type

Capacity

Crest length

Crest level

|

Overflow ski-jump and bucket with two vertical lift

gates, each 6.70m wide by 3.90m high

475 m3/s

13.4m

RL 1 161.30m |

|

Volume

of embankment

Earthfill

Filter

Rockfill

Total

|

3 810 800m

31 088 300m

31 836 200m

36 735 500m3

|

River

outlet works

|

0.15m

diameter bypass to provide Eucumbene Cove water

supply. Tunnel drainage valve modified for riparian

right releases of 0.07 m3/s.

|

| Foundation |

Closely

jointed hard siltstone and quartzite with overburden

of decomposed rock and slope-wash up to 6.10m deep. |

Other

features

|

Subsidiary

embankment containing 121 900 m3 of fill across

a low saddle in a ridge forming the left abutment. |

Reservoir

Gross Capacity

Active Capacity

Area at full supply level (FSL) |

4 798 400 x 103m3

4 366 500 x 103m3

14 500 ha |

Construction

period

|

May

1956 to May 1958 (the gated spillway was constructed

under a separate contract in 1977-78) |

Section through Eucumbene Dam (SMA,

1993: 17) |

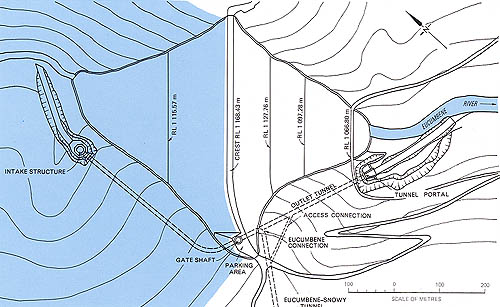

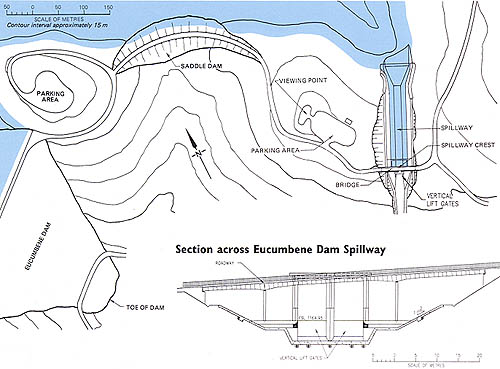

Plan

of Eucumbene Dam (SMA, 1993: 18)

Plan

of Eucumbene Dam (SMA, 1993: 18) |

Plan of Eucumbene Dam Spillway (SMA,

1993: 18) |

Tunnels

Approximately 98% of the Scheme's engineering features

are underground. Tunnels and pipelines, dug deep under

the Snowy Mountains, measure 145 kilometres, and with

80 kilometres of aqueducts, collect and divert the inflows

of the Snowy Mountains area.

Overview

of tunnel features (shown in order of length)

| Tunnel |

Length

km |

Excavated

section

metres |

Lined

section

metres |

Percentage

lined |

Year

of completion |

Eucumbene-Snowy

Eucumbene-Tumut

Murrumbidgee-Eucumbene

Snowy-Geehi

Tooma-Tumut

Murray 1 Pressure

Tumut 2 Pressure and Tailwater

Jindabyne-Island Bend

Guthega

Murray 2 Pressure

Tumut 1 Pressure

Tumut 1 Tailwater |

23.5

22.2

16.6

14.5

14.3

11.8

11.3

9.8

4.7

2.4

2.4

1.3 |

6.30

x 6.35

6.91

3.35 x 3.35

6.30 x 6.30

3.79 x 3.71

-

-

3.96 x 3.96

5.87 x 5.74

-

-

8.53 x 7.77 |

6.10 x 6.10

6.40

3.10 x 3.10

6.10 x 6.10

3.43

6.93 x 6.93

6.40

3.76

5.26 x 5.05

7.47 x 7.47

6.40

7.93 x 7.49 |

19.7

28.3

17.7

13.3

20.0

100

100

10.6

11.6

100

100

54.5 |

1965

1959

1961

1966

1961

1966

1961

1968

1955

1969

1959

1959 |

Summary

of principal features (in SI Units) - tunnels (SMA,

1993: 172)

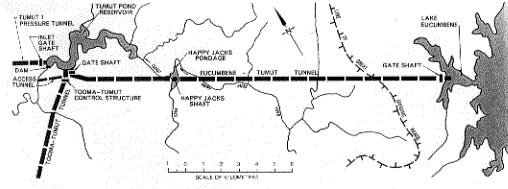

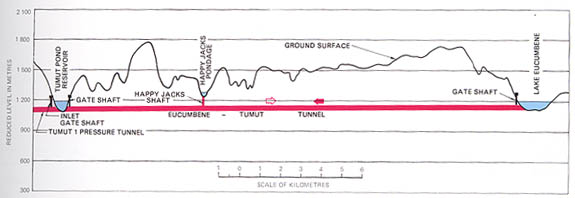

Specifications of Eucumbene-Tumut tunnel

(SMA, 1993: 25)

Plan of Eucumbene-Tumut tunnel (SMA,

1993: 25)

Profile of Eucumbene-Tumut tunnel (SMA,

1993: 25)

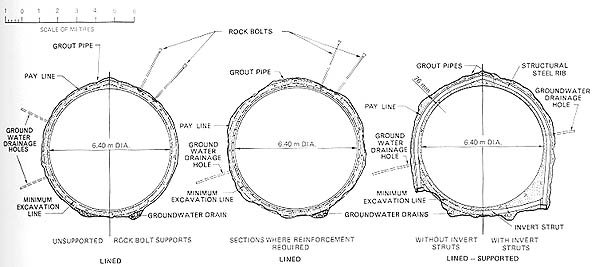

Tunnel cross-sections (SMA, 1993:

55)

Tunnelling

The longest tunnel is the Eucumbene-Snowy at 23.5 kilometres.

This tunnel diverts the water of the Snowy River from

Island Bend Pondage to storage in Lake Eucumbene, and

when required returns the water to the Snowy-Geehi Tunnel

at Island Bend. It took four years to build the tunnel,

a remarkable achievement when it is realised that the

geology of the Snowy Mountains is predominantly granite

and the diameter of the tunnel at maximum is 6.30 metres.

World

tunnelling records were established on the Scheme. In

1961, the Australian firm Thiess

Bros, were contracted for the Geehi section of the

Snowy-Geehi tunnel. In 1963, the firm established the

world record for hard rock tunnelling when 165 metres

of tunnel was formed in a week.

Swift

progress in tunnelling was the result of many factors,

but two deserve a special mention:

- the

sliding tunnel floor and

- rock

bolting.

Sliding

tunnel floor

The sliding tunnel floor comprises a large sectionalised

steel working floor platform, which carried rail

tracks, points and crossings, drilling gantry and

other tunnelling equipment. A hydraulic jacking

system moves each of the three floor units forward

in six stages.

|

(Raymond, 1999) |

Rock

bolting

Rock bolts were used to support the roof and walls of

major structures such as tunnels and power stations.

Steel bolts, of different length and spacing, were inserted

into the rock where they were found to be an excellent

anchorage for the rock.

Rock

bolts were tension bolts, that when placed, compressed

broken or jointed rock surrounding the tunnel and converted

the rock into a self-supporting arch structure. The

technique of grouting, between the bolt and the rock,

was developed for upward sloping bolts. It is claimed

that the Snowy engineers developed the world's first

successful method of grouting the holes between rock

and bolt.

Activity

1. List a range of hardware items that can be used to

join masonry or support loads in rock. State the advantages

and disadvantages of each support mechanism.

2. Make labelled freehand sketches to illustrate how

these support mechanisms work.

|

Power

stations

The seven power stations (two of which are underground)

house the large generators and turbines that produce

the electricity from water that is stored in the

Scheme's ponds and reservoirs.

Power

from the Snowy Mountains Scheme is transmitted at 330kV

to the electricity systems of NSW, Victoria,

the ACT, SA and Queensland. The Scheme can generate 3 756 megawatts,

representing about 17% of the generating capacity

of South Eastern Australia.

|

Lower

Tumut Switching Station at Talbingo in the final

stages of construction. Since 1973 this facility

has redistributed the power generated at nearby

Tumut 3 Power Station to Victoria and NSW along

330 000 volt transmission lines.

Photo: Bayram Ali

(Powerhouse Museum Collection) |

Towns

Towns like Eaglehawk, Sue City, Happy Jacks and Bella

Vista were purpose-built to service specific projects.

Home to hundreds or even thousands of people for several

years, they were dismantled after work was completed.

There were eight major townships.

| This

photograph depicts a street of houses for workers'

families at Eaglehawk near the Eucumbene Dam site

in winter in the mid-1950s. The town was built by

the NSW Public Works Department, which began the

Eucumbene Dam project. These buildings were prefabricated

in Sydney by Frank R. Wolstoneholme Pty Ltd and

transported to the Snowy by semi-trailer. Unfortunately

they were not specifically designed for use in the

freezing climate of the Snowy Mountains. External

water pipes froze in winter and the lack of insulation

and double-glazing added to the discomfort in cold

weather. |

Photo:

Bayram Ali

(Powerhouse Museum Collection) |

|