|

The Superbike has a special frame (monocoque), designed and

made in Australia, while the remaining components, disc wheels,

cranks, pedals, seat, chain etc., were made by the Italian

company, Campagnolo, of Vicenza, Italy. This company is also

a sponsor of the Australian Olympic cycling team.

| Monocoque

|

The

carbon fibre–polymer composite monocoque was shaped

to reduce aerodynamic drag. |

|

Handlebars |

The

conventional handlebars have been eliminated. Carbon fibre

handle grips are attached directly to the wheel forks. |

|

Weight |

The

lightweight frame (the bicycle weighs only 5 kg) provides

extra strength between the seat and pedals where the main

power is exerted. |

The

sweeping line of the Superbike optimises the aerodynamic shape

which, combined with the lightweight carbon fibre shell, requires

15 per cent less power to travel at a given speed than a conventional

tubular-framed racing bike.

Place

your mouse pointer over parts of the bike to find out more.

Materials

The choice of using carbon fibre technology, an area where

RMIT has special expertise, was an obvious one. Carbon fibre

components were already in use in other sporting equipment

where lightness, strength and stiffness were crucial, for

example in sailing skiffs. Thompson was determined from the

outset that the product which his team created should be suitable

for mass manufacturing, but at the same time it should have

exceptional quality and precision.

The

use of carbon fibre construction enables any shape to be formed.

Maximum strength is achieved with a minimum amount of material.

Carbon fibres have excellent strength and rigidity. This is

why carbon fibre is used so widely in space programs and Formula

One motor racing.

Production

of carbon fibres

| Carbon

fibres are produced by carbonising (heating to a very

high temperatures, but in the absence of oxygen to prevent

burning) organic fibres such as acrylics or high-strength

regenerated cellulose fibres. Precise control of carbonising

temperatures (up to 3000°C) determines the physical

properties of the resultant carbon fibre. (Fritz, 1986:

178) |

The

Colnago C-35 bicycle is a hand-made, Italian bicycle,

with carbon fibre monocoque frame and forks developed

by Colnago and Ferrari. Known as the 'Ultimate', this

unique bicycle also features gold-plated components.

Powerhouse Museum Collection. It was presented to the

Powerhouse Museum by Mr David Greatorex AO in 1995.

The

Colnago C-35 bicycle is a hand-made, Italian bicycle,

with carbon fibre monocoque frame and forks developed

by Colnago and Ferrari. Known as the 'Ultimate', this

unique bicycle also features gold-plated components.

Powerhouse Museum Collection. It was presented to the

Powerhouse Museum by Mr David Greatorex AO in 1995. |

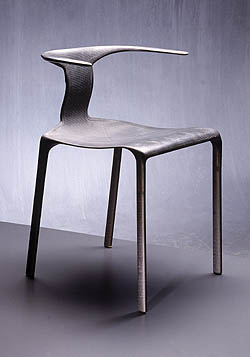

The

Lightlight experimental chair demonstrates the

use of carbon fabrics in an epoxy resin mould with unidirectional

meshing in carbon to achieve a useful, comfortable and

very light chair. It was designed by Alberto Meda and

made by Alias of Italy in 1987 and is an example of one

of the first applications of composite materials in the

furnishing industry. Powerhouse Museum Collection. It

was purchased by the Powerhouse Museum in 1989.

|

Activity

1. Outline the principles of monocoque construction.

2. What specific qualities does carbon fibre have that makes

it appropriate for use in this application?

|

![]()

![]()

![]()