| Engineering

the World's Fastest Bicycle |

|

|

|

By

Mr Lachlan Thompson FIEAust.

Research Leader Sports Technology, Department of Aerospace

Engineering,

Royal Melbourne Institute of Technology, Melbourne, Australia |

ABSTRACT:

Australian track cyclists won impressive victories at the

1995, '96 and '97 World Track Championships and the 15th Commonwealth

Games. The Australian team used with stunning effect a unique

carbon fibre monocoque bicycle designed and built by a project

team from the Royal Melbourne Institute of Technology (RMIT

University) and the Australian Institute of Sport (AIS). Developed

in consultation with Charlie Walsh, the national track cycling

coach, this new bicycle, the 'AIS/RMIT Superbike', has allowed

the Australian riders like Shane Kelly to set new records.

Continued development has resulted in over twelve World Championship

titles and four world records. Including the World record

for the kilometre Individual Time Trial set by Shane Kelly

in 1995.

The

development and application of new wind tunnel testing techniques

have resulted in a fifteen per cent reduction in power over

the traditional diamond frame. Extensive use of a water tunnel

and wind tunnel have enabled the team to optimise the frame

profile for minimum aerodynamic interference from the rider's

leg motion. Structural design loads were derived from track

testing with strain gauged frames. Finite element analysis

techniques were validated through extensive material testing.

Throughout the development program extensive use was made

of validated performance simulation. The simulation provided

evaluation of stiffness, aerodynamics and weight. These simulations

enabled rapid assessment of concepts. Track testing with power

meters and strain gauged frames were used to refine design

data and wind tunnel test techniques.

In

order to produce the resulting bicycle new manufacturing techniques

had to be developed. Unlike most equipment used by elite athletes

the AIS/RMIT 'Superbike' has been designed for low cost, high

volume manufacture. The hollow frame is moulded as a single

unit in a one shot process suitable for automation. The frame

was designed to accept standard group sets and wheels. The

AIS and RMIT University has lodged patents on the unique features

of the manufacturing process. Bicycle Technologies Pty Ltd

(Australia) has commenced commercial manufacture of track

and road variants. The New Zealand National Track Cycling

Team has selected the 'Superbike' for the 1997 and 1999 seasons.

It is anticipated that the technology will enable a new manufacturing

industry to be developed in Australia.

The

engineering development has resulted in the project winning

an Engineering Excellence Award from the Institution of Engineers

Australia, two Innovation Awards and the 1995 Velo News Award

for "Best Technical Development for 1995 in Road or Track".

This paper discuses the engineering techniques, research and

project management required to create the Australian Superbike.

DESIGN CRITERIA

The

stunning ride by Chris Boardman on the Lotus Bicycle(1)

in the Barcelona Olympics heralded a dramatic change in Olympic

track cycling. The UCI's rule change opened the door for the

monocoque bicycle to show its potential. Unlike the much later

Lotus Sport, Boardman's bicycle was a one-off with highly

specialised components. His ride did however set the stage

for a new era in competitive cycling

As

Chris Boardman rode to Olympic Gold the RMIT and AIS project

team set out to build a 'Superbike'. The RMIT-AIS team sought

a design that optimises weight, stiffness and aerodynamics

while conforming to the rules of the Union Cyclist Internationale

(UCI). The University was at the time seeking a suitable project

to demonstrate new low cost advanced composite manufacturing

techniques. The project team included engineers, technicians

and students from RMIT Aerospace Engineering, the AIS and

RMIT Industrial Design.

Australian

Olympic track cycling coach Charlie Walsh defined the initial

design criteria with the project team in late 1992. The resulting

bicycle must use a conventional group set of standard(3,6)

cranks, bearings, brakes, wheels, forks, handlebars, seat,

etc. Further criteria imposed by RMIT was that the design

must equal or exceed the structural stiffness of a steel bicycle

while offering lower aerodynamic drag and weight without compromising

reliability. It was also desirable for commercial purposes

that the resulting design be suitable for low cost, high volume

production.

| Seat

tube angle |

74

deg. ±0.05 deg. |

| Steering

tube angle |

74

deg. ±0.05 deg. |

| Bottom

bracket shell height |

55

mm ±1.0 below rear axle |

| Out

of plane twist |

±0.05

deg. |

Dimensional

tolerances(6) used in developing the 'Superbike'

In

this project the needs of the end user were paramount to the

success of the end product. Competition bicycles are made

to the rider's individual specific requirements. The client

specifications were defined and completely fulfilled. These

specifications included critical geometry as shown below and

certain subjective characteristics as ride and comfort. Stiffness,

strength, reliability and use of standard components were

achieved.

|

ENGINEERING

DESIGN

A

systems engineering approach was adopted for the project.

A requirement analysis was undertaken to establish the

design criteria and project milestones. The project

plan and budget were developed using the findings of

this analysis. Riding position and frame geometry defined

by the AIS were checked against a current AIS Olympic

steel frame. This same frame was later used to define

minimum stiffness criteria.

|

|

| Figure

1: Gary Neiwand test rides the strain-gauged prototype

|

|

Before

design could take place a mathematical performance model was

written and validated. The mathematical model was validated

against actual track performances using the SRM dynamometer

crank system. This permitted an extensive analysis of each

component in the bicycle system including the rider. The results

of this investigation showed that the frame and front fork

handle bars to be priority components for research. The requirement

analysis also identified that aerodynamic testing techniques

were not giving repeatable results of sufficient accuracy.

Development of improved wind tunnel techniques was considered

a high priority.

Traceability

in design was maintained throughout the project by maintaining

design files and technical reports on each task. Coupon testing

provided material properties for the Finite Element Models(4)

(FEM). Laboratory tests were used to prove structural details

before progressing to track testing.

Extensive

track and wind tunnel testing was used to validate design

changes. Each phase of the project has required critical evaluation

by both the design team and the national track cycling team.

Decisions were made at project or task meetings to ensure

prompt reporting of results and effective implementation of

new ideas.

Every

prototype was required to undergo structural testing for stiffness

followed by a general inspection. Modal analysis is being

developed as a tool for non-destructive inspection and quality

control. This technique of vibration analysis(2)

will provide a cost effective "finger print" technique

for production quality control.

AERODYNAMIC

DEVELOPMENT

In order to minimise aerodynamic drag new and innovative wind

tunnel testing techniques were developed. This included the

use of artificial legs to accurately study the airflow over

the bicycle. With this unique rig the aerodynamics of the

complete system could be represented.

Initial

investigations showed that the rider's legs dramatically influenced

the flow pattern(6) and resulting drag.

To obtain accurate and repeatable wind tunnel results with

live athletes was extremely difficult. The sensitive wind

tunnel balance required precise knowledge of the centre of

mass in order to apply corrections for induced forces due

to moment couples. In the development of the 'Superbike' the

rider was replaced with a pair of lightweight Styrofoam®

legs. A similar lightweight torso, head and arms could also

be fitted. The rear wheel was driven by an electric motor

beneath the wind tunnel floor. A simple belt drive under the

floor also drove the front wheel. By having the motor and

drive system part of the bicycle accurate and repeatable drag

measurement was possible.

By

May 1993 the project team arrived at a basic conceptual design

for a carbon fibre monocoque bicycle. A prototype of this

design was built for initial testing. Wind tunnel testing

was carried out to refine the aerodynamic shape. The instrumented

prototype was evaluated on the track by world champion sprint

cyclist Gary Neiwand. This testing allowed the engineers to

determine handling characteristics and the loads encountered

during competition. The data obtained was used to optimise

the design.

|

Subsequent

prototypes for testing and competition has resulted

in the 'Superbike' meeting or exceeding all of the design

criteria. Independent tests on the 1994 variant by Dr.

Neil Craig of the South Australian Institute(6)

of Sport at the Adelaide Superdrome showed the 'Superbike'

to require 5% less power than the then current steel

AIS Olympic tubular frame.

Further

improvement was made possible by designing a new wind

tunnel balance. The use of a 'hover board' bicycle mounting

eliminated balance interactions. This technique allowed

further refinement and development of the 'Superbike.

|

Figure

2: Moving artificial legs simulates the disturbed airflow

around the bicycle. |

| Year |

Configuration |

Power

@ 55kph |

| 1988–92 |

Steel

AIS Frame |

584

Watts |

| 1994 |

'Superbike'

XVth Commonwealth Games |

543

Watts |

| 1995 |

'Superbike'

carbon fibre blade forks and wing handlebars World Championships

Bogota |

522

Watts |

| 1996 |

'Superbike'

integrated fork-handlebars World Championships Manchester |

498

Watts |

Progressive

performance(6) improvement of RMIT-AIS 'Superbike'.

PRODUCTION

DESIGN

The requirement study showed that a one-size monocoque shell

could be developed to suit a wide range of rider size. One

single size of the 'Superbike' can accommodate riders from

1600 mm to 1900 mm in height.

The

'Superbike' is unique in that it has been designed from the

outset to be of a shape and structure that can be easily and

cheaply produced in high volume(3).

This manufacturing feature, a 'one size fits all concept',

removes the necessity for multiple and expensive tooling.

The use of a complete monocoque shell gives lower weight and

greater stiffness than achieved in previous racing bicycle

designs. This shell is completely hollow and requires no additional

core material. Careful structural optimisation has allowed

thin non-buckling skins to be used.

Refinement

of the manufacturing technique has allowed Patents(7)

on the process to be lodged. The Superbike is in production

at Bike Technologies Pty Ltd, Melbourne Australia. Continued

success in international competition has assisted the project

in commercialisation(2).

|

UCI

World Cup Colorado Springs USA, 17 Aug 94

Kathryn

Watt 1st 3000 m Ind Pursuit 3:41:91 Second

best ever career time

XV

Commonwealth Games, Victoria BC, Canada, September 94

Kathryn

Watt 1st 3000 m Ind Pursuit 3:48:52 Games

Record by over 3 sec

Brad

McGee 1st 4000 m Ind Pursuit 4:31:37 Games

Record by over 5 sec

Stuart

O'Grady 3rd 4000 m Ind Pursuit 4:35:20 Games

Record

McGee,

O'Grady, 1st 4000 m Team Pursuit 4:10:14

Games Record by over 7 sec Aitken, Woods&

O'Shannessey.

World

Junior Championships Italy, 1995

Shaun

Roberts 1st 3000 m Ind Pursuit

Narelle

Petersen 1st 2000 m Ind Pursuit

World

Championships, Colombia, September 1995

Shane

Kelly 1st 1000 m TT 1:00:613

World Record

B.

McGee, O'Grady, 1st 4000 m Pursuit 4:05:10

R. McGee, O'Shanessey.

Adelaide October 1995

Roberts,

Meany, World Record Junior team

pursuit

World

Championships, Manchester, UK, August 1996

Shane

Kelly 1st 1000 m TT

Kelly,

Neiwand, Hill 1st 200 m Olympic

TT World Record.

|

Competition

results for the Superbike (6,8).

STRUCTURAL

DESIGN

The 'Superbike' for the 1995 World Championships has the provision

for the flush mounting of instrumentation used in performance

trials. This allowed for an accurate assessment of the athlete

and equipment without the need to apply corrections for the

aerodynamic drag of the sensors. The ability to access track

test and race data for a pool of top athletes formed an integral

part of the development program(6).

Data from riders such as Bradley McGee, Kathryn Watt, Narelle

Petersen, Garry Niewand and Shane Kelly ensured that the configuration

was one that would benefit a diverse range of riders and riding

positions, further developing the mathematical performance

model.

Extensive

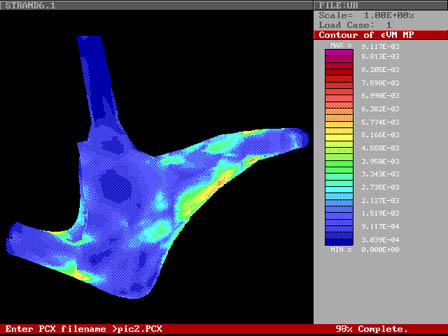

use was made of Computer Aided Drawing (CAD) to input data

to both Finite Element Analysis(3,4,5)

(FEM) and Computer Aided Machining (CAM) of production tools.

Software used in the project included Cadkey97 and STRAND6

as well as the in-house performance model.

Figure

3: STRAND6, FEM Analysis assisted lay-up optimisation.

|

|

Finite

Element Modeling(3,4) was used

to assist in the optimisation of the structure. This

was validated against the instrumented test bicycles,

which were ridden in competition conditions. Static

strength and fatigue life was of importance, as an AIS

track frame will average 10,000 kilometres of use per

annum. The same bicycle being used in training as well

as in competition. Modal analysis has been introduced

as a means of ensuring that each frame is of consistent

quality. Further development of this method of inspection

is planned.

|

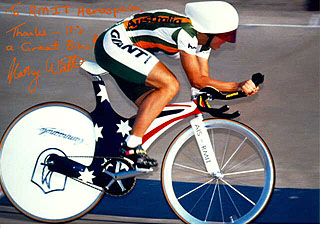

Figure

4: Kathryn Watt wins 'Superbike's' first ever race at

1994 UCI World Cup Colorado Springs USA. |

The

continued successful development(6)

of the 'Superbike' is not due to any one factor being superior.

Instead the credit goes to the application of a validated

mathematical performance model that can rapidly evaluate structural,

aerodynamic requirements and riding position.

REFERENCES

- Hill,

R. D. 'The Design and Development of the Lotus Sport

Pursuit Bicycle', Proceedings of the Institution of

Mechanical Engineers, pages 285 to 294, Volume 207, 1993,

UK.

- Lane,

T. 'Push to the Limit', The Australian Way, pages

84 to 87, November 1996, Australia.

- Wilson,

M. 'Super Roo Sets an Olympic pace', Overseas Trading,

October 1995, pages 6 to 9, Australia.

- Anon.

Australian Students Design Championship Racing Bicycle

Frame', MSCWorld, pages 12 to 14, Volume 5, Number 3,

November 1996, USA.

- Priestly,

D. 'Will the 'Superbike' be the Catalyst for an Aussie

Made Revival?' Bicycle Industry News, page 29, September

1994.

- Thompson,

L. and McLean, B. 'Super Roo Bicycle', Institution

of Engineers Australia, Victorian Division, Engineering

Excellence Awards, Paper, September 1995, RMIT.

- Thompson,

L.A.'Bicycle Frame', Patent PCT/AU95/00444, September

1995.

- Vaughan,

R. 'Australia Dominates Worlds', Bicycling Australia,

pages 44 to 45, November 1995, Australia.

|

![]()

![]()

![]()