|

|

|

|

| |

I need to find out all the facts in order to create the best, most

profitable and most sustainable product.

|

|

|

|

| |

Research

is needed at every point in the innovation cycle. Researchers

must assess many possibilities in order to identify the

most appropriate raw materials, the most efficient processes,

packaging and marketing strategies.

Research ranges from testing materials to asking consumers

about their buying habits. It relies on careful choice

of questions, for example:

- What's the cheapest, strongest material that can

be used for the purpose?

- How can I minimise the amount of material and energy

used to make or use the product?

- How effectively does my product do the job for

which it is designed?

- Is the product safe?

- How does my design allow for the product to be

recycled after its use?

- Who will buy this product, through which outlet

and for what price?

Thorough research is essential in the early stages of

innovation; this is often carried out in universities

or CSIRO and other government organisations. Continual

reassessment is important as the product develops; this

research is often carried out by industry.

Research that involves scientific testing needs to be

unbiased and carefully controlled. In any scientific experiment

or test, the test process is repeated and only one thing

(called a variable) is changed at a time. As well as the

people, plants or animals being tested in the experimental

group, there must be another group that is used as a control.

For that control group the variable is not changed, providing

a baseline against which experimental results are compared.

The individuals in the control group are as similar as

possible to those in the experimental group and are treated

the same way apart from the variable being tested.

For example, to test whether plants can survive without

water, take a large group of plants that are all the same

size, age and species. Divide the large group into two

to create one experimental and one control group. Grow

the plants in similar soil, give them the same amount

of sunlight but stop watering the experimental group.

Keep watering the control group. You can be pretty sure

that if the experimental group dies while the control

group remains healthy, the death is due to lack of water.

Tests of medical products often include double-blind trials

in which neither the patient nor the doctor knows whether

the patient is receiving medicine or a placebo. This allows

researchers to rule out the effects of "expectation

of success" by either the doctor or patient. A placebo

is a substance which has no medical properties but has

the same form, eg tablet or cream, as the active medicine.

A placebo has no physiological function but might assist

the patient psychologically. The medicine and placebo

are packaged in the same way but can be identified by

a number provided by the researchers. The doctor simply

records the number on the patient's file. Researchers

are the only ones who know which packages contain medicine

and can correlate results at the end of the trial.

International Centre for Scientific Research http://www.cirs.net/indexenglish.htm

CSIRO Australia http://www.csiro.au

|

|

|

| |

Australian tea tree oil — research for a healthy

future

Tea tree oil is a powerful antiseptic. The aboriginal

Bunjulung people of the NSW north coast have known about

it for thousands of years. They use it to take the sting

out of cuts and insect bites, and to successfully treat

bacterial, viral and fungal infections. Tea tree oil is

extracted from the leaves of a small native Australian

tree, Melaleuca alternifolia.

The oil contains high concentrations (up to 35%) of an

alcohol called terpinen-4-ol that's thought to be responsible

for most of the oil's antimicrobial activity. There are

more than 100 other chemicals in the oil.

In 1925, Arthur Penfold, a chemist and curator of Sydney's

Technological Museum (now the Powerhouse Museum), demonstrated

that tea tree oil was 13 times more powerful than phenol,

the standard antiseptic of the time. To do this, Penfold

gathered leaves from the bush, steamed them to release

the oil, and distilled the oil from the water. He then

tested the oil on the bacterium that causes typhoid.

For ten years Penfold provided oil to doctors and dentists

for clinical trials. Results were so convincing that tea

tree oil was sent to war with troops during World War

II. During the war, however, penicillin was introduced

to treat bacterial infections. The world fell in love

with new antibiotics like penicillin and forgot about

tea tree oil.

Interest in tea tree oil was rekindled in the 1980s. Growing

bacterial resistance to antibiotics is partly responsible

for this renewed interest. The tea tree industry has developed

dramatically from one relying on harvesting of naturally

occurring plants to one characterised by highly mechanised

intensive plantations. Australia leads the world in the

supply of high quality tea tree oil and associated products.

It currently produces about 400 tonnes of oil a year,

most of which is exported to North America and Europe.

Research has played a vital role in the development of

the industry and will be essential for its future.

|

|

|

|

| |

|

| Close up of a tea tree leaf.

Courtesy Thursday Plantation. |

|

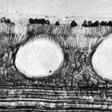

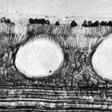

| A section through a tea tree leaf showing a vein

beneath three oil glands. Technological Museum, Sydney. |

|

|

Research

for a growing industry

There are about 300 tea tree growers in Australia, all

hoping to compete successfully in a world market. The

industry body, the Australian Tea Tree Industry Association

(ATTIA), is working closely with the Rural Industries

Research & Development Corporation (RIRDC) to develop

a profitable and environmentally sustainable industry.

They hope to lead the world in marketing, value-adding,

product reliability and production. Research is needed

in this young industry in order to meet those goals.

Current research is under way in a number of areas. Two

examples of the importance of research to the tea tree

industry are:

- Testing the safety and effectiveness of tea tree

oil in laboratory and clinical trials designed to

meet the standards of Australian and international

regulatory authorities. This will lead to development

of new products in the areas of animal and plant health

and industrial hygiene. Safety tests will provide

information for formulation and labelling of products.

- Developing production systems that are both ecologically

sustainable and profitable. Maximising the yield of

oil will make best use of valuable resources, such

as land and water.

For more information about the tea tree industry see the http://www.teatree.org.au or http://www.rirdc.gov.au.

|

|

|

| |

|

| Professor Thomas Riley. Courtesy University of

Western Australia Department of Microbiology. |

|

|

Testing

safety and effectiveness

Tea tree oil must meet national and international standards

for safety and efficacy before it can be accepted as a

valid antiseptic agent. Until recently, claims about its

power were based on anecdotes or on outdated scientific

methods.

For pharmaceutical and medical communities

to accept tea tree oil as a bona fide antimicrobial

agent, the results of investigations need to be published

in international journals acceptable to these groups.

Only when this occurs will tea tree oil move out of

the realms of quackery and alternative medicine.

Professor Thomas Riley, Department of Microbiology at

the University of Western Australia, 1998.

Professor Riley leads a team of scientists investigating

the antimicrobial activity and safety of tea tree oil.

So far they have demonstrated, using test tube (in vitro)

trials, that the oil is active against a wide range of

bacteria, viruses and fungi. For more information about

their research see http://www.meddent.uwa.edu.au/teatree.

|

|

|

| |

|

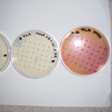

| Testing bacteria growth in tea tree oil. Courtesy

University of Western Australia Department of Microbiology. |

|

|

Laboratory trials

Before registering a health-care antiseptic, the Food

and Drug Administration of the USA requires a list of

all the organisms that are killed by the antiseptic. Riley's

team designed experiments to test the susceptibility of

organisms to tea tree oil. They aimed to identify the

minimum concentrations of oil that would inhibit growth

or kill particular micro-organisms. They tested many micro-organisms

including:

- Escherichia coli, which causes gastroenteritis

- Pseudomonas aeruginosa, a penicillin-resistant

bacterium that infects wounds, burns, and the urinary

and respiratory tracts

- Methicillin-resistant strains of Staphylococcus

aureus (Golden staph), a major cause of hospital-acquired

infections

- Streptococcus and Staphylococcus species, which

cause skin infections including impetigo

- Propionibacterium acnes, which plays a role in

acne

- Candida albicans, a fungus that causes thrush infections.

The team grew the organisms in several warm broths containing

varying concentrations of tea tree oil for 24 hours. They

found that the growth of most of the organisms was inhibited

at an oil concentration of 0.25%v/v (volume/volume, ie

0.25ml of tea tree oil added to 99.75ml of broth). Most

of the organisms died at 0.50% while an oil concentration

of 3.0% was needed to kill the penicillin-resistant bacteria

Pseudomonas aeruginosa. All of these findings have been

published in international journals.

Clinical

trials

Controlled, double-blind clinical trials are under way

to test the effectiveness of the oil in treating a number

of infections, including thrush, impetigo, methicillin-resistant

golden staph, and cold sores caused by the Herpes labialis

virus. These projects are funded by RIRDC and Australian

Bodycare Pty Ltd, and involve hospital patients in Western

Australia and NSW.

|

|

|

| |

|

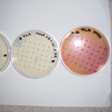

| Patch tests containing tea tree oil are used

to determine skin sensitivity. Courtesy University of

Western Australia Department of Microbiology. |

|

|

Skin sensitivity trials

Skin sensitivity trials have been carried out to determine

the prevalence and characteristics of allergy or sensitivity

to tea tree oil. This research is essential for the formulation,

packaging and labelling of products. The research involved

testing more than 200 healthy volunteers for allergy to

tea tree oil using two different tests, the prick test

and the patch test. Ten different tea tree oils were tested.

The prick test involved applying oil to the skin, then

breaking the skin with a needle. Other common allergens,

including dust mite and grass, were tested at the same

time (on different areas of skin!) to determine whether

the volunteers were more or less allergic than average.

Any reactions were noted immediately.

The patch test involved sticking squares of material soaked

in different concentrations of oil onto each patient's

skin. Patches were left in place for some time and then

checked. This test detected delayed irritant reactions

and allergic contact dermatitis. Any volunteer who showed

a reaction to tea tree oil was tested again with 100%

oil, 10% oil and then the major oil components.

The prevalence of allergy in the whole group was 2.9%

(up to a possible 4.8% if mild reactions are included).

Incidence of reactions to the other common allergens indicated

that the test subjects were somewhat 'more allergic' than

the general public.

Irritant reactions were particularly concentration dependent,

which means that many of these reactions should be avoidable

if a lower concentration of oil is used in formulations.

Very few reactions occurred in response to tea tree oil

components. Subsequent tests demonstrated that allergic

reactions are generally caused by oxidation products of

tea-tree oil, rather than the fresh oil itself. These

findings provided valuable information regarding the formulation

and packaging of the oil products. That is, low concentrations

should be used and the oil should be stored in brown glass

bottles, away from heat and light in order to prevent

oxidation.

|

|

|

| |

|

|

A tea tree plantation. Courtesy Thursday Plantation. |

|

| A tea tree oil production system. Courtesy Thursday

Plantation. |

|

|

Developing production systems

Research in this area aims to boost the amount of oil

produced by each tree in order to maximise the yield from

available resources, including land and water. The main

focus is on the selective breeding of high-yielding trees

and on the appropriate management of trees in different

growing areas and climates.

Selective breeding of trees

Growing the highest yielding trees in a plantation makes

sense. In the past, people grew seeds collected from a

limited number of bush trees. CSIRO and NSW Agriculture

have increased the quality of seed available for growers

as a result of eight years' research at the Wollongbar

Agricultural Institute, near Lismore, NSW. They have created

a 'seed orchard' which produces high quality seed.

First, they assessed the variability in oil yield and

quality from individual trees in their field trials. They

progressively culled inferior trees and developed controlled

pollination techniques to produce desirable hybrids. Genetic

technologies were also employed in the research. They

identified the genes responsible for oil yield and quality,

and breeding lines can now be DNA fingerprinted. The first

batch of improved seed was distributed in 1997, and the

second-generation seed orchard was established from seedlings

in 2001.

A 30% increase in oil yield is predicted through use of

this improved seed, and further culling of the orchards

over time is expected to give improvements of 60%. The

results of this ongoing research will help to maintain

the financial viability of the industry.

Managing plantations

A research project in the Atherton Tableland of North

Queensland has implications for the way trees are managed

for maximum oil production. In the 1990s, tobacco quotas

fell and farmers on the Tableland replaced their tobacco

crops with tea trees. Previously the tea tree industry

had been located almost exclusively in northern NSW and

was very new to Queensland.

In these areas tea trees are being grown

in different climates and on different soil types. Little

was known about the levels of production or how to manage

the trees. Growers had used information from NSW to

help establish plantations; however there was a real

need for research work to adapt and alter this information

and determine the factors which affect oil concentrations

and yields in these areas.

Dr James Drinnan, RIRDC Communications.

The research involved collaboration and cooperation between

the NSW Department of Agriculture, the Australian Tea

Tree Industry Association, and the Rural Industries Research

and Development Corporation.

Because all tea tree farms on the Atherton tablelands

are irrigated, much of the research focussed on the best

way to tailor water use to the needs of the crop. Irrigation

is a major expense, so it needs to be as cost-effective

as possible. A water monitoring system (Enviroscan) was

installed on a farm that had soil and water use typical

of the area. Sensors were installed in the soil at 100-800

mm depths to determine the water requirements of seedlings,

mature trees, and trees regrowing after harvest.

Researchers also measured changes in oil yields from the

trees throughout the year and in response to irrigation.

Research in New South Wales had already shown that the

amount of oil obtained one day after irrigation was less

than half that obtained from the same crop four days after

irrigation. This sort of information is crucial for the

maximisation of yield from a plantation.

Other research has shown that tea trees have high requirements

for iron, zinc and copper. And the optimum harvesting

time is either December or just after the wet season in

April.

Thus research has demonstrated that the major factors

influencing yield are genetics, irrigation and nutrition.

It is essential to start with seeds from good genetic

stock, to regularly irrigate and fertilise the crop, and

to harvest at the appropriate time. This information has

changed the farming practices and profits of growers in

the Atherton Tableland and is potentially valuable for

growers wishing to establish plantations in other parts

of Australia.

The Rural Industry Research and Development Corporation

funds many of the research projects currently under way

in the tea tree industry. Reports on those projects can

be found at http://www.rirdc.gov.au/reports.

|

|

|

| |

|

| Tea tree oil products sold by Thursday Plantation.

Courtesy Thursday Plantation. |

|

|

The

impacts

Through the research efforts of academics and the Australian

tea tree industry, the properties of tea tree oil are

becoming recognised and accepted within mainstream medicine.

Production methods have been improved in the last 20 years

such that the volume of tea tree oil produced in Australia

has increased by almost 20 times. More than 80% of this

oil is exported, usually as bulk oil.

|

|

|

| |

Links and references

Australian Tea Tree Industry Association http://www.teatree.org.au

Rural Industries Research & Development Corporation

http://www.rirdc.gov.au

Wollongbar Agricultural Institute http://www.agric.nsw.gov.au/general/centres/wollongbar

CSIRO http://www.csiro.au

University

of Western Australia Tea Tree Research http://www.meddent.uwa.edu.au/teatree

Technical paper by UWA researchers http://www.teatree.co.uk/research.htm

Tea Tree Oil UK http://www.teatree.co.uk

Thursday Plantation http://www.thursdayplantation.com.au

Key

organisations

Australian Tea Tree Industry Association

Rural Industries Research & Development Corporation

University of Western Australia Tea Tree Oil Research

Group

Thursday Plantation

Jobs

and skills

Scientists (biologist, chemist, immunologist, horticulturalist)

Plantation manager

Farmer

Nurse

Discussion

questions

K-6

1. What did the Aboriginal Bunjulung people of the NSW

north coast use tea tree oil for?

2. Using a tape recorder, interview an expert (botanist,

horticulturist, gardener) about how to grow a tea tree.

3. Research an Indigenous Dreaming story about tea tree.

4. Using a digital camera record images of tea trees and

tea tree products. Look for trees in gardens, (eg. botanical

gardens), in plant nurseries or in your local area. Make

a collage, drawing or diagram which shows the process

of making tea tree oil.

7-10

1. Research how Indigenous peoples used tea tree for antiseptic

purposes. Draw a timeline to show how different people

in different times used tea tree oil to treat infection.

2. As a market researcher, what kinds of questions would

you ask consumers about a product like tea tree oil? Design

a questionnaire to ascertain buying habits.

3. List the main micro-organisms used in laboratory trials

to test tea tree oil’s antiseptic qualities. Discuss

the findings of these trials.

4. What is ecological sustainability? How important is

it to the tea tree industry?

11-12

1. What kinds of questions might a scientific researcher

ask when investigating the best way to create a product?

2. What is usually required before a pharmaceutical or

medical preparation is accepted as safe and effective?

3. Why are skin sensitivity trials so important?

4. Perform a first-hand investigation to measure the pH

value of a range of tea tree products.

|

|

|

|

|

|

|

|