Jameson Cell ore process

1985

improved flotation process for ore separation

Here's a new version of an old Australian mining innovation.

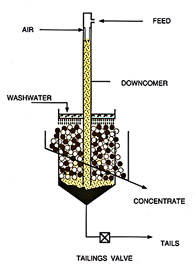

The froth flotation process is used to separate minerals from ores at metal mines around the world. Mineral ores are ground into small particles and put into chemical baths (called cells). Air bubbles are forced up through the cell and the mineral particles stick to them. The bubbles form a mineral-rich froth on the surface, which is then scraped off.

In the 1980s a new kind of flotation cell was developed by Professor Graeme Jameson and students at the University of Newcastle. Crushed ore, in a liquid slurry, is fed into a vertical pipe and draws air down with it. Mixing and adhesion occur more quickly and in a smaller space than in a conventional cell. This improves the separation and collection process. A higher percentage of mineral is recovered, improving the economics of a mine; this also means that less mineral is left in the tailings, from where heavy metals could leach into the soil and pose a hazard.

As there is no need for a motor, air compressor or moving parts, the new cells are energy efficient and cheap to operate and maintain.

After trialling and further development at Mount Isa Mines in the mid 1980s, Jameson Cells were installed at mine sites in several countries to improve recovery rates of lead, zinc, copper, nickel and other ores. They are also used to recover fine coal that would otherwise go to waste.

Who Did It?

Key Organisations

MIM Holdings Pty Ltd : development

University of Newcastle : research

Key People

Graeme Jameson : inventor

Jim Fewings : development team leader

Further Reading

'The Jameson Flotation Cell'

Alan Kennedy

Mining Magazine, October 1990

Links

MIM Process Technologies, Jameson

Cell

MIM Holdings

Minerals Council of Australia

Related Innovations

Froth flotation process

|