Moldflow design software

1978

software to design moulds for plastic parts

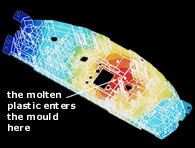

In injection moulding, molten plastic is squirted under high pressure into a mould. Different flow and cooling rates of the plastic can cause flow marks on the surface and warping of the finished product, which makes it look untidy.

Designing a new mould is often the most expensive single investment in product development - so it's better if you find out where problems might happen before you actually make the mould.

That's where Moldflow computer software comes in. It simulates the injection-moulding process, trialling any shape of mould that the designer can imagine. It displays colour-coded pictures of the way molten plastic will flow into the mould and how the plastic will shrink or warp when it cools. Engineers can use this information to design extra cooling channels into the mould and to beef up plastic sections that might warp. The toolmaker uses the computer-generated design to make the mould.

Using Moldflow, designs for plastic products can be completed without the immense cost of making models or testing and modifying a prototype mould.

Moldflow was first proposed by Colin Austin in 1970 and is an early example of computer aided design and simulation. Launched in 1978, it became the leading product in its field, used by over 500 companies worldwide including BMW cars and Hawker-Siddeley aircraft.

After Moldflow was launched demand was such that in 1981 it opened a London office, closely followed by one in the USA in 1982. In 2000 Moldflow was listed as a public company with headquarters in the USA and offices in many countries including Japan, China, Italy, Netherlands, Spain, Germany, Taiwan, UK, Korea, Singapore, and Sweden.

Who Did It?

Key Organisations

Moldflow Pty Ltd : R&D, design, programming

Key People

Roland Thomas : general manager

Colin Austin : conceived & developed idea

Jean Austin : director

Further Reading

Making it: innovation and success in Australia's industries

R Renew

Powerhouse Publishing, Sydney, 1993, pp 93-94.

Links

Moldflow

Cooperative Research Centre

for Intelligent Manufacturing Systems and Technologies

Questions & Activities

Moldflow design software

|