Rib Loc pipe

1980

watertight pipe made of spiral plastic strip

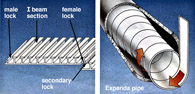

The Rib Loc pipe-making process was invented in the 1980s by Bill Menzel of Adelaide. It produces pipe by winding out a continuous roll of interlocking ribbed plastic sheet to form a cylinder (a bit like the way cardboard toilet roll tubes are made).

The pipes are just as strong as concrete ones, but they're lighter. And because they are wound into pipes 'on site' by a special machine, they can be transported to the site in a compact roll. Rib Loc pipe is often used as formwork in building concrete columns.

Expanda Pipe is an innovation on this innovation. It takes standard Rib Loc and uses it to reinforce and reline existing concrete, steel or terracotta pipes without having to dig them up. A small hole is dug and an opening is made in the old pipe. Then a stationary Expanda Pipe machine winds Rib Loc down inside and along the pipe.

By 1991 Expanda Pipe was being made with recycled polyethylene from used milk and juice containers, yet another innovation! The Adelaide factory reuses thousands of tonnes of plastic each year.

In 2000 a system called Rota Loc was introduced by Rib Loc. This process uses a winding machine that travels along the inside of a deteriorated pipeline and produces the spiral wound plastic liner as it moves.

Rib Loc pipe is sold in more than 40 countries in Africa, Asia, Europe, South America and North America. In 1999-2000 the company?s turnover was $24 million.

Who Did It?

Key Organisations

Rib Loc Aust Pty Ltd : R&D, design, manufacture

Key People

Bill Menzel : inventor Rib Loc managing director

Dave Momimee : designer

Gil Vance : designer

Alan Sutton : designer

Further Reading

'Old bottles turn into new wealth'

Richard Jinman

The Australian, 15 October 1991.

Links

Rib Loc Group Ltd. Animations

of how Expanda Pipe works

Related Innovations

Humespun Pipe

|