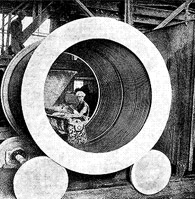

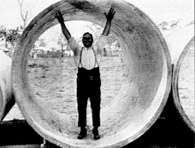

Humespun pipe

1910

concrete pipe made by centrifugal casting

Sewerage and water-supply systems are a hidden but essential part of urban living and a field of constant innovation.

The first European Australians built brick-lined sewers and aqueducts and used pipes made of wood or terracotta, essentially 2000-year-old technology. But these old methods proved too expensive and slow for rapidly expanding suburbs that were a long way from water reservoirs and dams.

In 1910 Walter Hume perfected a method for making steel-reinforced concrete pipes. He showed that if concrete was pumped into a spinning, cylindrical mould lined with reinforcing mesh, centrifugal force flung it evenly around the sides and squeezed out the water. The resulting pipes were very dense, waterproof, strong and relatively lightweight.

Walter and his brother formed a company to manufacture spun concrete pipes for sewage and drainage. The Hume brothers invested the profits from their pipes and culverts into research and development to improve the design of the products and the quality of the manufacturing processes.

Humes' was one of the earliest Australian manufacturing companies to set up factories and distribution networks in all Australian states and overseas. Hume's company and its licensees have made Humespun concrete pipes on every continent ever since.

Who Did It?

Key Organisations

Hume Bros Cement and Iron Company Ltd : R&D, design, manufacture

Key People

Walter Hume : inventor, company founder

Ernest Hume : company founder

Further Reading

Making it: innovation and success in Australia's industries

R Renew

Powerhouse Publishing, Sydney, 1993.

Links

Technology in Australia 1788-1988, ATSE

Spun concrete pipe patent example

CSR

Questions & Activities

Humespun pipe

Related Innovations

RibLoc pipe

|