Froth flotation process

1904

process for separating mineral ores

At the end of the 19th century, metal prices had slumped and around every Australian mining town mountains of waste were piling up, much of it still containing valuable metals like zinc. The problem facing Guillaume Delprat was to find a cheap way to reprocess the waste and get at that zinc.

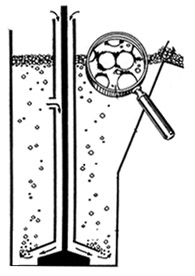

Delprat, an engineer from the Basque region of Spain, had migrated to Australia to become assistant general manager of BHP in 1896. Delprat realised that if the waste was crushed and put into a chemical bath and a stream of bubbles was made at the bottom, bubbles coated with zinc ore particles would float to the top and form a froth that could be skimmed off.

His patent application on behalf of BHP was disputed by Charles Potter, a Melbourne brewer who had patented a similar method for purifying liquids. Potter was unsuccessful in court but the method is now known as the Potter-Delprat process.

Further research showed that a number of different chemicals, including eucalyptus oil, could be added to the bath to separate different metals from the waste. The process is still being developed and improved upon.

Within ten years 5.7 million tonnes of accumulated waste had been reprocessed with a value of 30 million pounds ($60 million). The froth flotation process for separating mineral ores was so much more efficient than previous methods it was soon adopted at metal mines worldwide.

It greatly extended the life of the Broken Hill mines, making it, in economic terms, the most important Australian innovation of the early 20th century.

Who Did It?

Key Organisations

Broken Hill Proprietary Ltd : R&D, design, operation

Key People

Charles Potter : researcher

Guillaume Delprat : mine manager

A D Carmichael : metallurgist

Further Reading

The rush that never ended

G Blainey

Melbourne University Press, Melbourne, 1969.

Links

ATSE

Technology in Australia 1788-1988

Questions & Activities

Froth flotation process

Related Innovations

Jameson Cell ore process

Durable heavy rail technology

Casting thin sheet steel

|